SUR IRON AND STEEL COMPANY P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUR IRON AND STEEL COMPANY P.LTD.

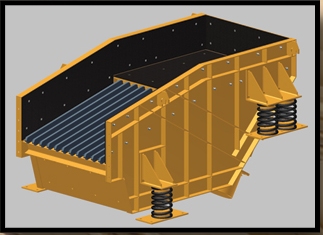

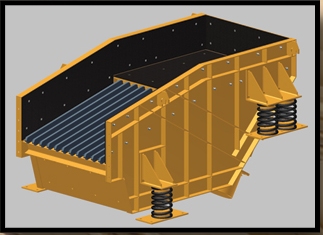

Vibro Feeder

We Deal with the toughest SISCO vibrating Feeder& Screens with unbalance drives are economical dependent & pollution free conveying equipment for all bulk material. They are used for a wide range of material such as � Granite, Iron Ore, Limestone, Dolomite, coal, Copper & Zinc Ore, Coke, Bauxite etc.

SPECIAL FEATURES

High output & dependability against low capital & operating cost.

High centrifugal force in relation to the dead weight.

Twin unbalanced Heavy duty motors for trouble free operation.

Ease of maintenance.

Wide range application & various combination of sizes & decks for screening.

Minimum moving parts � less maintenance

Heavy duty coil spring absorb all impact load.

No spillage, leakage or carry back of loads

Stepped deck does effective separation in the Grizzly feeder.

Feeder can be suspended or floor mounted.

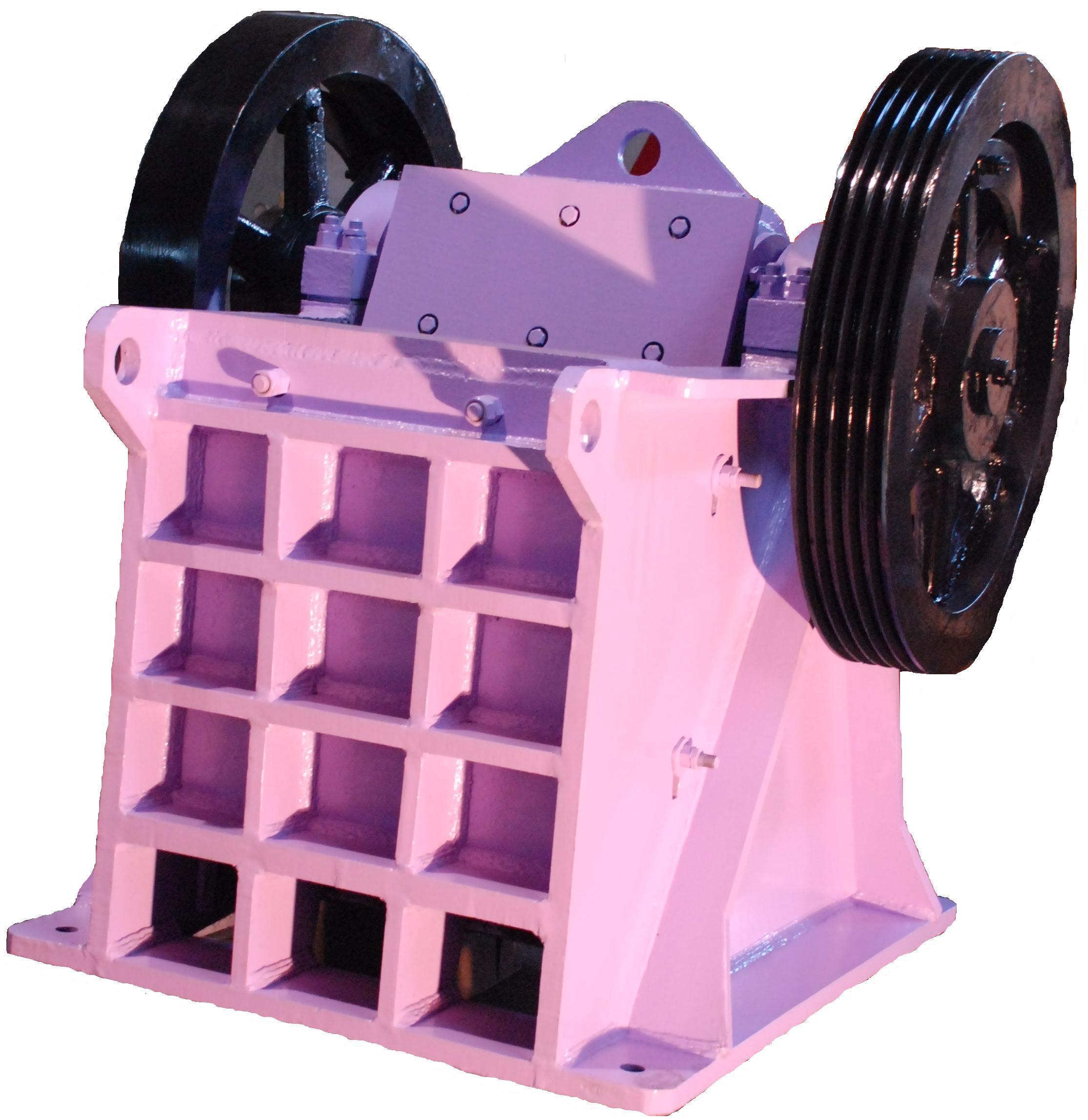

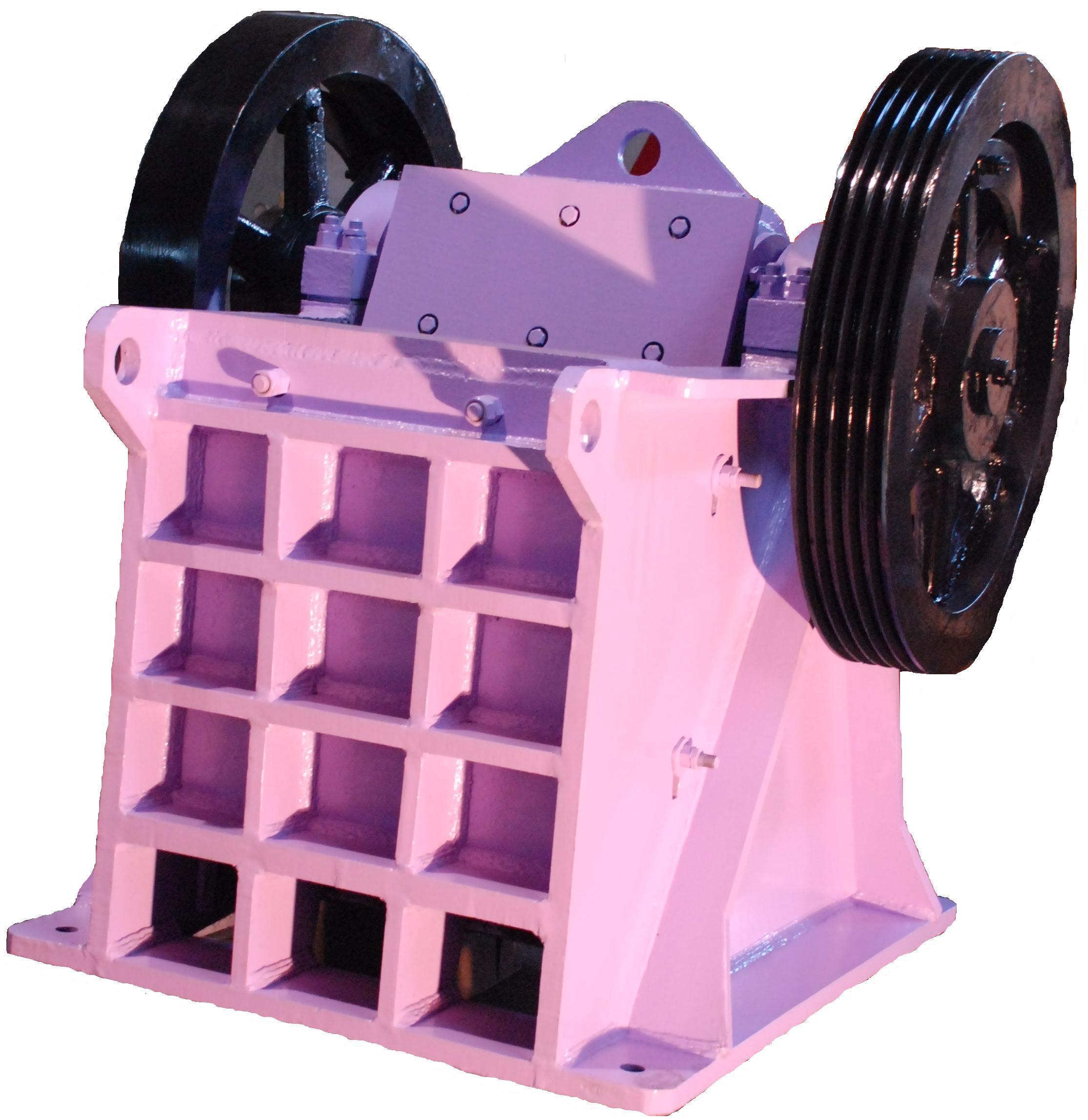

Jaw Crusher Single Toggle

We Deal with the toughest

- Efficient utilisation of power

- Longer manganese steel jaw. Life

- Reversible jaws

- Easy gap adjusting arrangement

- Higher impact with lesser rubbing

- Easy maintenance

The Sisco single toggle jaw crusher is acknowledged in its field. Equipped with anti- friction bearings and fabricated all-welded steel construction duly stress relieved, which not only gives added strength but eliminates any risk of costing failures. Apart from exceptionally hard materials, for which the Sisco crusher is the ideal machine, if meets practically every requirement of the Quarry, Grovel plant, Construction and Mining fields.

Gyratory Cone Crusher

SISCO Gyramatic HYDRAULIC GYRATORY CRUSHER

We deal with the toughest

SISCO Gyramatic HYDRAULIC ROLLER BEARING CRUSHER

‘SISCO’ Gyramatic Hydraulic Roller Bearing Gyratory Crusher, which apply a unique hydraulic control system, are used in Primary, Secondary or Tertiary crushing. Discharge setting of the crusher is controlled automatically by charging oil quantity in the hydraulic cylinder. Optional Remote Control System is also provided.

SALIENT FEATURES

- Roller bearing crusher

- Completely Hydraulic controlled and automatic release of uncrushed material

- Cubical shape of crushed materialism

- Easy Adaptability

- Easy hydraulic gap-setting even during operation

- Simple maintenance

- Fail safe lubrication system

- Higher speed

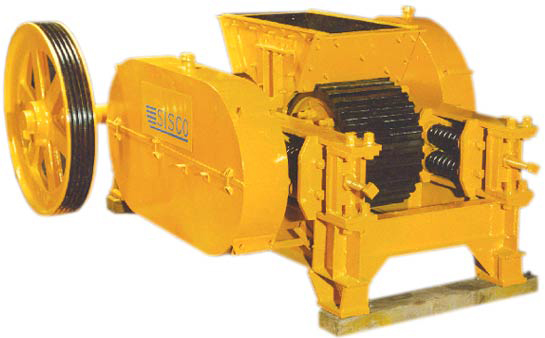

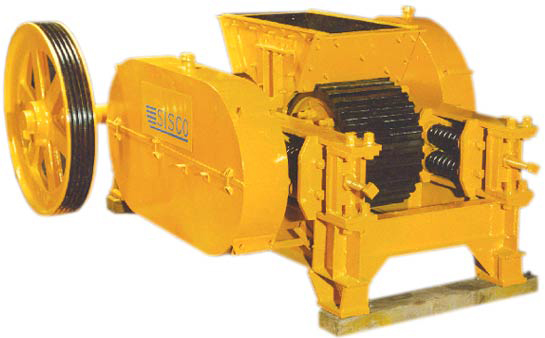

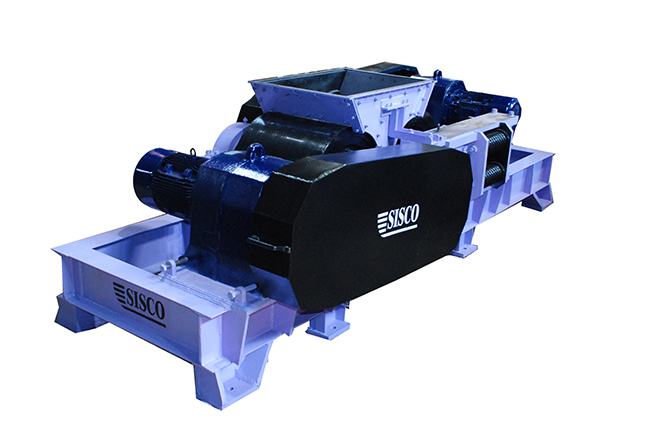

Double Roll Crusher

APPLICATION

The Roll Crusher usually saves head-room and weight, compact in structure and economical in first cost. lt is capable of large output AT SMALL RATIOS OF REDUCTION. For these reasons, the roll crusher lends itself to portable use or for fine crushing where ratio of reduction does not exceed 3 to 1. Corrugated rolls of different pitch and depth are used for greater RATIO OF REDUCTION and can take BIGGER FEED SIZE.

CAPARCITY AND REDUCTION RATIO

The double roll type of crusher pinches the aggregate only once. To avoid excessive wear upon the roll tyres, it is important that the pinch should be immediate, positive and without slippage. Consequently, larger feed sizes should be avoided, and the ratio of reduction should be kept within the 3 to 1 limit. Any attempt to exceed the permissible ratio of reduction c causes slippage which leads to increased wear upon the tyres, excessive spring action, oversize product and undue unkeep expense. Refer to table on back page for capacities and maximum size of feed recommended. ‘SISCO’ CD-Series Roll Crushers successfully Crushes Aggregates, Limestone, lron Ore, Dolomite Coal etc.

CONSTRUCTION

‘SISCO’ Double Roll Crusher is a very substantially built machine. The longitudinal frame members are heavy steel joist reinforced with extra supports under each bearing cage and at the end. Cross- members are also heavy steel joist which form a rectangular main frame of exceptional strength and rigidity. Two heavy roll units, one fixed and one movable are mounted on this frame.

ROLL UNITS

Each roll unit consists of a replaceable manganese steel roll shell, ground V-shaped on the inner periphery. This is mounted on a set of expanding conical rings, which function together as co-acting wedges. These are pulled together by heavy bolts so as to grip manganese shell firmly between them. Both the hubs of co-acting wedges are keyed to a heavy alloy steel shaft mounted on heavy duty self- aligning spherical double row roller bearing. The fixed roll drives the movable roll through a set of star gears. The heavy duty rollers haft bearings are enclosed in a steel bearing housing. The housing for the fixed rolls haft is bolted to the main crusher frame with the housing cage. Movable Rolls haft bearing housing along with slides are fitted in between the slide plates of the main frame and the top slide plates. Slides fitted with each bearing housing are fastened with high tensile counter shanked screws. The movable roll shaft bearing housing is floating and is placed between the gap adjusting shims on one side and spring assembly on the other side. These heavy duty springs assembled with high tensile studs absorb unwanted shocks and thus saves the equipment from damage. This also allows the passage of uncrushable material. Shims between top plate mounting stand and the movable shaft bearing housing fix the distance between rolls and thus determine the discharge opening

ADJUSTMENT

The movable roll assembly is supported by set bolt buffer plates stands and bolts. The other side of the movable roll assembly has provision for inserting adjusting shims. Once these set bolts are released then the adjusting shims can be either added or subtracted. Addition or subtraction of adjusting shims decreases or increases the gap between the rolls. Once the gap is fixed then theses set bolts are once again tightened.

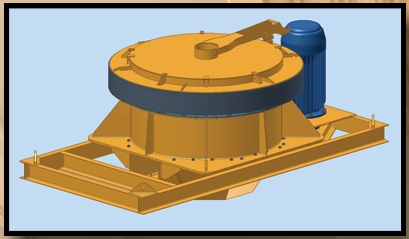

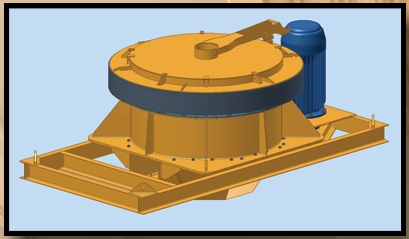

Vertical Shaft Impacter

Description / Specification of Vertical Shaft Impacter

We are involved in offering a wide range of Vertical Shaft Impacter to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vertical Shaft Impacter. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Vibrating Screen Linear Motion

We Deal with the toughest SISCO vibrating Feeder& Screens with unbalance drives are economical dependent & pollution free conveying equipment for all bulk material. They are used for a wide range of material such as � Granite, Iron Ore, Limestone, Dolomite, coal, Copper & Zinc Ore, Coke, Bauxite etc.

SPECIAL FEATURES

- High output & dependability against low capital & operating cost.

- High centrifugal force in relation to the dead weight.

- Twin unbalanced Heavy duty motors for trouble free operation.

- Ease of maintenance.

- Wide range application & various combination of sizes & decks for screening.

- Minimum moving parts � less maintenance

- Heavy duty coil spring absorb all impact load.

- No spillage, leakage or carry back of loads

- Stepped deck does effective separation in the Grizzly feeder.

- Feeder can be suspended or floor mounted.

Sand Classifier

For Sand Production & Washing

- 65 years of experience and proven track record in solving all requirements from a 10 to 175 TPH.

- The first sand plant was operative in 1970 for construction of Dhanikari Dam in Andaman.

- You may select your exact requirement from SISCO�s wide range of crushers .

Conveyor

CONVEYOR:

The range of single roll crushers available from SISCO are designed for the primary reduction of Coal, Lignite, Coal, gypsum, Shale, Slate, Oxide, fireclay, Salts, chemicals, Phosphate rock Lime, Ceramic Clay, Bone, Graphite and other friable materials. All machines are provided with automatic mechanical overload and are ideally suitable for choke feeding.

CONSTRUCTION FEATURE: FRAME & BREAKER PLATE

The design of the crusher is extremely simple consisting of a heavy welded rigid box type frame which will stand the most severe service: crushing roll and breaker plate are mounted in the frame. The breaker plate is hinged at its upper end and held in position by a pair of adjustable tension rods at the lower edge by means of which the clear opening between the breaker plate shoe and the surface of the roll can be varied to give a range of product sizes. The breaker plate is fabricated from a heavy steel plate and provided with wear resistant renewable bolted liners. The breaker plate itself can be easily removed from the top of the Crusher. The heavy spring on the tension rod cushions the Crusher againast severe shock.

Double Roll Breaker

APPLICATION

The Roll Crusher usually saves head-room and weight, compact in structure and economical in first cost. lt is capable of large output AT SMALL RATIOS OF REDUCTION. For these reasons, the roll crusher lends itself to portable use or for fine crushing where ratio of reduction does not exceed 3 to 1. Corrugated rolls of different pitch and depth are used for greater RATIO OF REDUCTION and can take BIGGER FEED SIZE.

CAPARCITY AND REDUCTION RATIO

The double roll type of crusher pinches the aggregate only once. To avoid excessive wear upon the roll tyres, it is important that the pinch should be immediate, positive and without slippage. Consequently, larger feed sizes should be avoided, and the ratio of reduction should be kept within the 3 to 1 limit. Any attempt to exceed the permissible ratio of reduction c causes slippage which leads to increased wear upon the tyres, excessive spring action, oversize product and undue unkeep expense. Refer to table on back page for capacities and maximum size of feed recommended. ‘SISCO’ CD-Series Roll Crushers successfully Crushes Aggregates, Limestone, lron Ore, Dolomite Coal etc.

CONSTRUCTION

‘SISCO’ Double Roll Crusher is a very substantially built machine. The longitudinal frame members are heavy steel joist reinforced with extra supports under each bearing cage and at the end. Cross- members are also heavy steel joist which form a rectangular main frame of exceptional strength and rigidity. Two heavy roll units, one fixed and one movable are mounted on this frame.

ROLL UNITS

Each roll unit consists of a replaceable manganese steel roll shell, ground V-shaped on the inner periphery. This is mounted on a set of expanding conical rings, which function together as co-acting wedges. These are pulled together by heavy bolts so as to grip manganese shell firmly between them. Both the hubs of co-acting wedges are keyed to a heavy alloy steel shaft mounted on heavy duty self- aligning spherical double row roller bearing. The fixed roll drives the movable roll through a set of star gears. The heavy duty rollers haft bearings are enclosed in a steel bearing housing. The housing for the fixed rolls haft is bolted to the main crusher frame with the housing cage. Movable Rolls haft bearing housing along with slides are fitted in between the slide plates of the main frame and the top slide plates. Slides fitted with each bearing housing are fastened with high tensile counter shanked screws. The movable roll shaft bearing housing is floating and is placed between the gap adjusting shims on one side and spring assembly on the other side. These heavy duty springs assembled with high tensile studs absorb unwanted shocks and thus saves the equipment from damage. This also allows the passage of uncrushable material. Shims between top plate mounting stand and the movable shaft bearing housing fix the distance between rolls and thus determine the discharge opening

ADJUSTMENT

The movable roll assembly is supported by set bolt buffer plates stands and bolts. The other side of the movable roll assembly has provision for inserting adjusting shims. Once these set bolts are released then the adjusting shims can be either added or subtracted. Addition or subtraction of adjusting shims decreases or increases the gap between the rolls. Once the gap is fixed then theses set bolts are once again tightened.

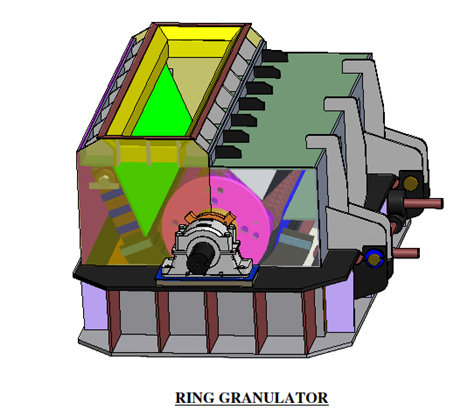

Ring Granulator

Salient Features

- Robustly designed for high capacity crushing (200-1500 TPH ) of ROM coal and similar friable materials.

- Unique crushing action with higher reduction ratio and lower power consumption.

- Large freed size relative to motor diameter.

- Uniform product size.

- Easy gap adjusting arrangement between the cage & ring hammers to compensate wear for maintaining product size.

- Low maintenance cost & long service life.

Crushing Screening System

Description / Specification of Crushing Screening System

We are involved in offering a wide range of Crushing Screening System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crushing Screening System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.